the company

Pasqualetti & Masi Srl was founded in 1970 by Alessandro Pasqualetti and Franco Masi and operates in the engineering machine construction field (special component manufacturing according to customers’ specifications, machining generally for the supply of mechanical spare parts).

Since its inception, it has been active in various industrial sectors, including the construction, agricultural machinery, food, shipbuilding, oil and gas, railway and tramway industries.

Today, as a result of the generational change within the company and especially thanks to the leadership provided by Laura Pasqualetti, an excellent example of female entrepreneurship, Pasqualetti & Masi srl is constantly evolving and innovating its machinery, seeking to predict future trends in the market in order to be ready to meet customers’ new needs. Furthermore, the company has developed the skills and gained considerable expertise in the field to be competitive in an increasingly demanding market.

Production and sectors

Safety, reliability and professionalism are the key values that set us apart.

RAILWAY INDUSTRY

In the railway industry, along with the supply of products and spare parts, the company has provided, since the 1990s, an overhaul/maintenance service of the tram and railway brake cylinders, particularly thanks to a patent related to the encapsulation of the these. Additionally, since 2011, following the introduction of the SGC (Competence Management System) certification and that of the COCS 30 by Trenitalia, Pasqualetti & Masi Srl has been training and certifying its maintenance staff in accordance with ANSFISA guidelines. It has extended its maintenance competence to the entire braking system (e.g. distributors, valves, relays, etc.) and has also collaborated with Fondazione FS for the maintenance of the Tourist Railways.

Today, it therefore has certified staff capable of working on brake components and is equipped with test benches for release tests.

Within the railway sector, it is also the exclusive sale representative in Italy of the lubrification systems produced and supplied by the German company REBS Zentralschmiertechnik GmbH since the 2000s.

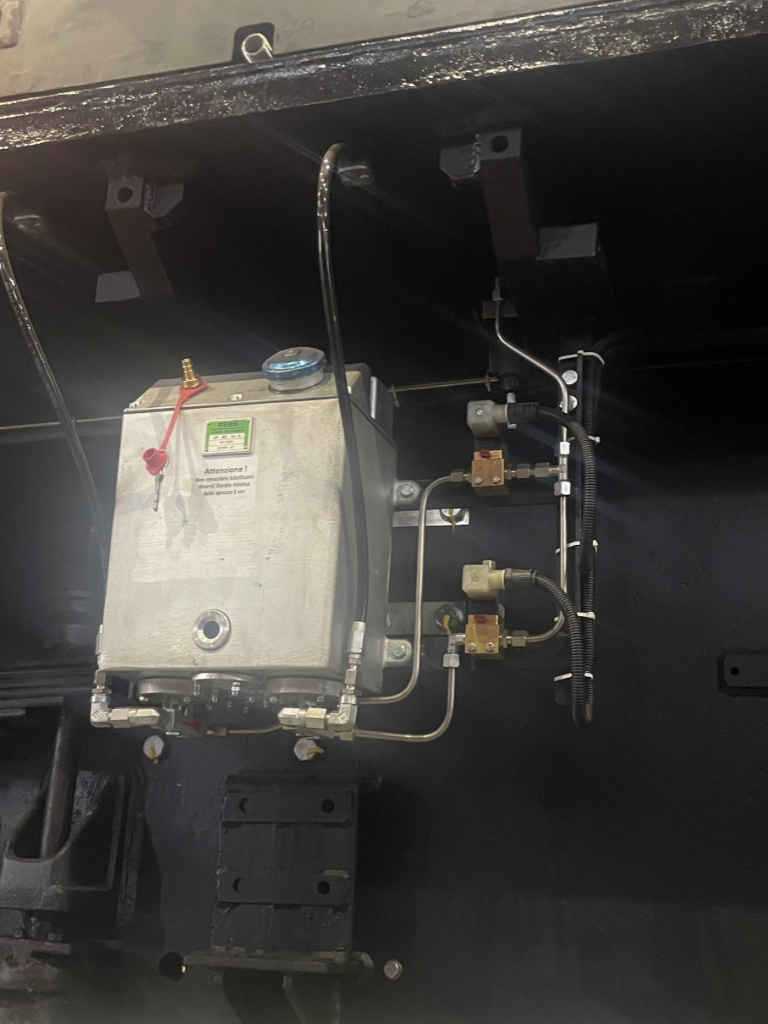

A recent installation of REBS Ungibordo Plant on a shunting locomotive D.245 January 2023 – Detail of grease tank

Today, it therefore has certified staff capable of working on brake components and is equipped with test benches for release tests.

Within the railway sector, it is also the exclusive sale representative in Italy of the lubrification systems produced and supplied by the German company REBS Zentralschmiertechnik GmbH since the 2000s.

A recent installation of REBS Ungibordo Plant on a shunting locomotive D.245 January 2023 – Detail of grease tank

food industry

We offer services for the supply of mechanical parts according to customers’ requirements, specialising particularly in the manufacturing of components made of stainless steel, brass, bronze and plastics such as Teflon, techtron and the like.

NAUTICAL INDUSTRY

We provide products for boat engines specifically designed for the maritime industry. We have collaborated with Fincantieri spa in the construction of the cruise ships (specifically, that of Costa Romantica).

OIL AND GAS INDUSTRY

In the oil and gas industry, we offer products for oil production, transport and processing, including parts for pumps and valves, tank accessories and transportation systems. We use high-pressure and stress-resistant materials to ensure maximum safety and professionalism.

DESIGN INDUSTRY

In the design industry, we produce special components for stainless steel structures and interior design furniture

Machinery

INDUSTRY 4.0

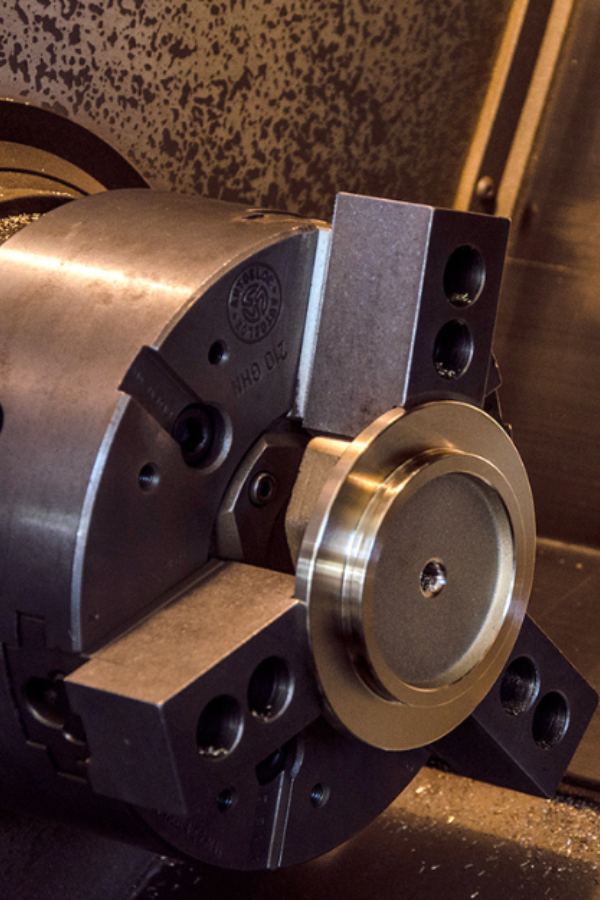

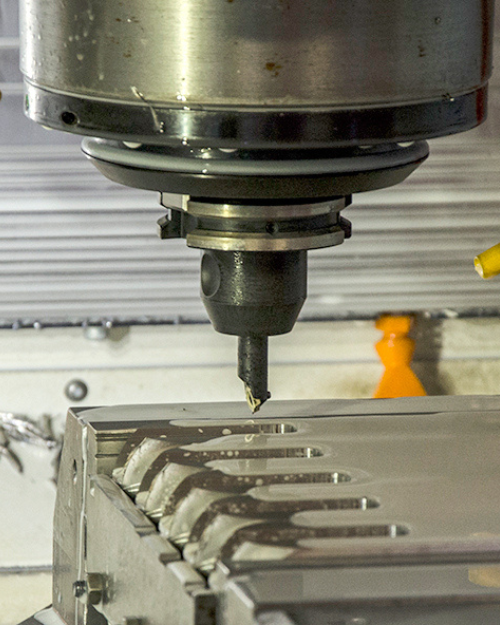

With respect to the mechanical machining sector, our company has machinery operating by metal removal.

We have recently invested in technological innovation and opportunities related to the ‘Industry 4.0’ and we therefore have the latest generation of machinery, lathes and CNC machining centres to perform customized mechanical constructions.

Max. turning diameter 400 mm. Max. piece length 800 mm

X-axis stroke 276 mm

Y-axis stroke 120 mm

Z-axis stroke 755 mm

Max. turning diameter 580 mm

Max. workpiece length 1000 mm

X-axis stroke 310 mm

Z-axis stroke 1080 mm

Altimeter Mitutoyo mod. LH-600E

Panel dimensions 1650x650 mm

Longitudinal x-axis stroke 1500 mm

Transverse y-axis stroke 650 mm

Vertical z-axis stroke 600 mm

Teoma rotary panel

Maximum turning diameter 400 mm

Max. piece length 1000 mm

X-axis stroke 310 mm

Z-axis stroke 1080 mm

Panel dimensions 1400x650 mm

Longitudinal X-axis stroke 1250 mm

Transverse y-axis stroke 600 mm

Vertical z-axis stroke 685 mm

Scotti rotary panel

Panel dimensions 1400x650 mm

Longitudinal x axis stroke 1250 mm

Transverse y-axis stroke 600 mm

Vertical z-axis stroke 685 mm

Scotti rotary panel

Ask for a quote!

Fill out the form to request a quote o receive more information.

How to reach us

FROM ROME

Take Siena Bettolle exit, proceed towards Siena, take FI-SI highway to Firenze.

Take Poggibonsi Nord exit, proceed towards Certaldo to Gambassi Terme (Badia a Cerreto).

from Bologna

Take Firenze Certosa Exit, take highway FI-SI to Siena.

Take Poggibonsi Nord Exit, proceed toward Certaldo to Gambassi Terme, loc. Badia a Cerreto.